ababoneleli Steel

Ngaba ungathengisa intsimbi engatyiwayo?

I-soldering steel stainless inokubonakala njengomsebenzi onzima, kodwa akunakwenzeka. Khawufane ucinge ukuba ungumenzi wesacholo, unikwe umsebenzi wokulungisa i-heirloom yosapho oyithandayo eyenziwe ngentsimbi engatyiwayo. Uyazi ukuba ukuwelda ayisiyiyo inketho, kodwa umthengi ufuna ukuba isiqwenga sibonakale sisihle njengesitsha. Ingaba wenza ntoni? Uguqukela kwi-soldering.

So can you solder stainless steel?

Ewe, i-soldering steel stainless inzima kuba inendawo ephezulu yokunyibilika kwaye ayikwamkeli ngokukhawuleza i-solder. I-Welding okanye ibrazing isetyenziswa ngokuqhelekileyo endaweni yoko.

Ngezixhobo ezifanelekileyo kunye nobuchule, i-Welding okanye i-brazing ingaba yindlela efanelekileyo yokudibanisa insimbi engenasici ngaphandle kokonakalisa isiqwenga. Kweli nqaku, siza kuphonononga i-ins kunye nokuphuma kwe-soldering steel stainless, kwaye sikubonise ukuba kunokwenzeka ukwenza ibhondi eyomeleleyo nenhle eya kuhlala iminyaka ezayo. Ke, ukuba unomdla wokwazi ukuba ungayithengisa na intsimbi engenasici, qhubeka ufunda.

Zeziphi iintlobo ezahlukeneyo zeendlela zokuthambisa ngentsimbi engenastainless?

Kukho iindlela ezininzi zokuthengisa intsimbi engenasici, nganye ineengenelo zayo kunye nokungona kwayo. Ezona ndlela zixhaphakileyo ziquka:

Ukujongisa isilivere:

Le ndlela isebenzisa i-alloy yesilivere ukwenza ibhondi eyomeleleyo, ehlala ixesha elide phakathi kwamaqhekeza entsimbi.TIG ukuwelda:

I-welding ye-Tungsten Inert Gas (TIG) ingasetyenziselwa ukudibanisa isinyithi esingenasici. Le ndlela isebenzisa i-electrode ye-tungsten ukutshisa isinyithi kunye nentonga yokuzalisa ukujoyina iziqwenga.Ukuwelda kwe-MIG:

I-Metal Inert Gas (MIG) welding ingasetyenziselwa ukudibanisa intsimbi engenasici. Le ndlela isebenzisa ukutya kocingo kunye negesi ye-inert ukudala ibhondi eqinile phakathi kwamaqhekeza.Ukuxhathisa ukuwelda:

Le ndlela isebenzisa ukuxhathisa kombane ukutshisa insimbi engenasici kunye nokudala ibhondi phakathi kwamaqhekeza.Ukuwelda ngeLaser:

Le ndlela isebenzisa i-laser beam ephezulu yamandla ukutshisa kunye nokudibanisa amaqhekeza ensimbi.

Ukukhethwa kwendlela kuya kuxhomekeka kwisicelo esithile kunye neemfuno zamandla, ukuqina, kunye nokuxhathisa ukubola. Kubalulekile ukukhetha indlela eya kubonelela ngebhondi eqinile kwaye ethembekileyo yokusetyenziswa okujoliswe kuyo.

Loluphi uhlobo lwesoda ekufuneka lusetyenziselwe intsimbi engatyiwayo?

Xa i-soldering steel stainless, kubalulekile ukukhetha uhlobo olufanelekileyo lwe-solder. Ngokuqhelekileyo, abathengisi abanomxholo ophezulu wesilivere bayacetyiswa kuba banikezela ngamandla okubambisana kunye nokuxhathisa ukubola. I-alloys ye-solder eqhelekileyo yensimbi engenasici iquka ii-solder-based solders, ezifana nezo zinesilivere, ubhedu kunye ne-zinc.

Kukwabalulekile ukusebenzisa i-flux eyenzelwe ngokukodwa intsimbi engenasici. I-flux inceda ukukhusela i-oxidation ngexesha lenkqubo ye-soldering kwaye ikhuthaza ukunamathela phakathi kwe-solder kunye ne-stainless steel surface. Ezinye iifluxes ezicetyiswayo zokutywinwa kwensimbi engenasici ziquka ezo ziqulethe i-boron, i-zinc chloride, okanye i-ammonium chloride.

Kubalulekile ukulandela imiyalelo yomenzi kuzo zombini i-solder kunye ne-flux ukuqinisekisa ukubamba ngokufanelekileyo kunye nokuphepha nayiphi na imiba enokubakho ngokubola okanye amandla. Ukongeza, kubalulekile ukucoca ngokufanelekileyo kwaye ulungiselele umphezulu wensimbi engenasici phambi kokuba uthengiselwe ukuqinisekisa ibhondi eyomeleleyo nehlala ixesha elide.

Ngaba kunzima ukuthengisa intsimbi engenasici xa kuthelekiswa nezinye izinto?

Ewe, i-soldering steel stainless inokuba ngumngeni ngakumbi kunezinye izinto ngenxa ye-conductivity ephezulu ye-thermal kunye ne-coefficient ephantsi yokwandisa i-thermal.

Kudinga ukushisa okuphezulu kunye nohlobo olukhethekileyo lokukhupha ukususa i-chromium oxide layer ekhusela insimbi engenasici kwi-corrosion. Ukongezelela, isinyithi esingenasici sinomkhwa wokujika kunye nokugqwesa xa sibonakaliswe kubushushu, okwenza ukuba kubaluleke kakhulu ukusebenzisa iindlela ezifanelekileyo kunye nezixhobo zokuthintela umonakalo.

Nangona kunjalo, ngokulungiswa okufanelekileyo, izixhobo ezifanelekileyo kunye nezixhobo, kunye nobuchule obufanelekileyo, i-soldering steel stainless inokuphunyezwa ngempumelelo. Abashicileli abanamava kunye nabasebenzi bentsimbi bahlala bekwazi ukufikelela kwiziphumo ezigqwesileyo kunye ne-stainless steel soldering.

Ngaba isinyithi esingenasici sinokuthengiswa ngaphandle kokusetyenziswa kwe-flux?

Yes, ukuguga kwentsimbi engenasici ngaphandle kokuguquguquka kunokwenzeka, kodwa akukhuthazwa.

I-Flux inceda ukususa nayiphi na i-oxides okanye i-contaminants ebusweni bensimbi engenasici, evumela ukuba i-solder ibophe ngokufanelekileyo. Ngaphandle kwe-flux, i-solder ayinakubambelela kakuhle, ibangele amajoyina abuthathaka okanye angaphelelanga. Ukongezelela, ngaphandle kwe-flux, inkqubo ye-soldering inokuthatha ixesha elide, kwaye amathuba okushisa okanye ukulimaza insimbi engenasici ayanda. Kungcono ukusebenzisa i-flux efanelekileyo kwi-solder yensimbi engenasici ukuqinisekisa iziphumo ezilungileyo. Uhlobo lwe-flux esetyenzisiweyo luxhomekeke kwindlela ye-soldering kunye ne-alloy ethile yensimbi engenasici. Ukusebenzisa i-flux engalunganga kunokukhokelela kumgangatho ophantsi wamalungu okanye kunye nokubola ekuhambeni kwexesha. Ke ngoko, kubalulekile ukubonisana nengcali okanye ubhekisele kwizikhokelo zomenzi ukuqinisekisa ukuba kusetyenziswa umbane ochanekileyo kwinkqubo yokuthengisela.

Ngaba ungathengisa amabanga ahlukeneyo entsimbi etyiwayo kunye?

Hayi. Ukudibanisa amabakala ahlukeneyo ensimbi engenasici kunye kunokuba ngumngeni ngenxa yamanqanaba ahlukeneyo omxholo we-alloy kunye nokwakheka.Kunconywa ukuba ugweme ukuthungatha amabakala ahlukeneyo ensimbi engenasici, njengoko kunokubangela ukubola kunye nokuphazamiseka kweempawu zoomatshini.

Nangona kunjalo, ukuba i-soldering iyimfuneko, kubalulekile ukusebenzisa i-solder ehambelana namabakala omabini ensimbi engenasici kunye nokuqwalasela ngokucokisekileyo idizayini edibeneyo kunye nokulungiselela ukuqinisekisa ukuba ibhondi eqinile kunye neyomelele. I-Welding okanye i-brazing inokuba lukhetho olungcono lokujoyina amabakala ahlukeneyo ensimbi engenasici. Kuhlala kucetyiswa ukuba udibane ne-metallurgist eqeqeshiweyo okanye injineli ye-welding ngaphambi kokuzama ukuthengisa amabakala ahlukeneyo ensimbi engenasici kunye.

Bubuphi ubushushu obufunekayo ukuze udibanise intsimbi engatyiwayo?

Ubushushu obufunekayo kwi-solder yensimbi engenasici kuxhomekeke kuhlobo lwe-solder kunye ne-flux esetyenziswayo. Ngokuqhelekileyo, iqondo lokushisa eliphakathi kwama-600 kunye nama-800 degrees Fahrenheit liyafuneka ukunyibilikisa i-solder kunye nokudala ibhondi ngensimbi engenasici. Kubalulekile ukuba uqaphele ukuba ukugqithiswa kwensimbi engenasici kunokubangela umonakalo kwiipropati zayo kwaye kukhokelela ekubunjweni kwemimandla echaphazelekayo yokushisa.

Ukongezelela, kubalulekile ukusebenzisa i-iron soldering okanye i-torch kunye nokulawula ubushushu obulungileyo ukukhusela ukushisa kunye nokuqinisekisa ukufudumeza okuhambelanayo kwe-solder joint. Kukwacetyiswa ukuba kusetyenziswe isalathisi seqondo lokushisa njenge-thermocouple ukubeka iliso kwiqondo lokushisa elidibeneyo ngexesha lenkqubo yokuthengisa.

Ngokubanzi, iqondo lokushisa elifunekayo kwi-soldering steel stainless liphezulu kunelo lifunekayo ekuthengiseni ezinye izinto ezifana nobhedu okanye ubhedu, kwaye kubalulekile ukulandela iindlela ezifanelekileyo zokubethelela ukufezekisa ukudibanisa okunamandla kunye nokuqina.

Ngaba akhona nawaphi na amanyathelo okhuseleko anokuthatyathwa xa kuthengiswe ngentsimbi engatyiwayo?

Yewe, thKukho amanyathelo amaninzi okhuseleko ekufuneka uwathathe xa u-soldering steel stainless. Okokuqala nokuphambili, kubalulekile ukuba sebenza kwindawo engenamoya ukuphepha ukuphefumla nayiphi na imisi eveliswa ngexesha lenkqubo yokuthengisela. Kwakhona kubalulekile ukuba nxiba izixhobo zokukhusela, njengeeglavu kunye neeglasi zokhuseleko, ukukhusela ukutshisa kunye nokuvezwa kwi-soldering flux.

Ukongeza, kubalulekile ukuba sebenzisa isinyithi esine-soldering kunye nokulawula ubushushu ukuphepha ukutshisa insimbi engenasici, enokubangela ukubola kunye nokunciphisa izinto eziphathekayo. Kukwacetyiswa ukuba sebenzisa i-soldering paste okanye i-flux eyenzelwe ngokukodwa insimbi engenasici ukuqinisekisa ibhondi eyomeleleyo kunye nokuthintela umonakalo kwizinto eziphathekayo.

Ekugqibeleni, kubalulekile ukuba landela iinkqubo ezifanelekileyo zokulahla kuyo nayiphi na inkunkuma eyenziwe ngexesha lenkqubo yokuthengisela; ezifana ne-soldering flux esetyenzisiweyo kunye nezilahlwa ze-solder. Ezi mathiriyeli zinokuba yingozi kwindalo esingqongileyo ukuba azilahlwanga kakuhle.

Ubunzima bensimbi engenasici buchaphazela njani inkqubo ye-soldering?

Ubunzima bensimbi engenasici bunokuchaphazela inkqubo ye-soldering ngeendlela ezimbalwa. Intsimbi etyebileyo idinga ubushushu obuninzi ukuze isetyenziswe ukuze i-solder ihambe ngokufanelekileyo kwaye idibanise nentsimbi. Oku kunokwenza inkqubo ibe ngumngeni ngakumbi, njengoko intsimbi inokujika okanye yonakaliswe ukuba kushushu kakhulu. Ukongeza, isinyithi esityebileyo sinokufuna ixesha elide lokufudumeza, elinokunyusa umngcipheko wokutshisa kwe-solder okanye ukutshisa okutshisa ngokukhawuleza.

Kwelinye icala, intsimbi ebhityileyo inokuchaphazeleka ngakumbi kwi-warping okanye ukunyibilika ukuba kufakwe ubushushu obuninzi. Kwakhona kunokuba nzima ngakumbi ukudala ibhondi eqinile phakathi kwe-solder kunye nentsimbi ukuba intsimbi incinci kakhulu.

Ngoko ke, kubalulekile ukuqwalasela ubukhulu bensimbi engenasici xa kucwangciswa inkqubo ye-soldering. Ulawulo olufanelekileyo lobushushu kunye nobuchule bubalulekile ekufezekiseni ubudlelwane obuphumelelayo kunye obuqinileyo phakathi kwe-solder kunye nentsimbi, kungakhathaliseki ukuba bubunzima bayo.

Zeziphi ezinye izicelo eziqhelekileyo apho i-soldering isetyenziselwa isinyithi esingenasici?

I-soldering isetyenziswa ngokuqhelekileyo kwizicelo ezahlukeneyo apho insimbi engenasici ibandakanyeka. Eminye imizekelo eqhelekileyo ibandakanya ukwenza izacholo, ukudityaniswa kombane, imibhobho yamanzi, kunye nokulungiswa kweemoto.

Ukwenza ubucwebe, i-soldering isetyenziselwa ukudibanisa amacandelo ahlukeneyo eqhekeza, njenge-clasps kunye namatyathanga. Kwindibano ye-elektroniki, i-soldering isetyenziselwa ukunamathisela amacandelo kwiibhodi zeesekethe eziprintiweyo. Kwimibhobho, i-soldering isetyenziselwa ukudibanisa imibhobho yobhedu kwizixhobo ezenziwe ngensimbi engenasici. Ekulungisweni kweemoto, i-soldering isetyenziselwa ukulungisa iinkqubo zokukhupha kunye nezinye izinto ezenziwe ngensimbi engenasici.

I-Soldering inikezela ngeendleko-esebenzayo kunye nendlela efanelekileyo yokujoyina amacandelo ensimbi engenasici, ngakumbi kwiimeko apho i-welding ingenakusebenza okanye iyimfuneko. Nangona kunjalo, kubalulekile ukukhetha indlela efanelekileyo ye-solder kunye nezixhobo zesicelo esithile ukuqinisekisa ukudibanisa okunamandla kunye nokuqina. Ukongeza, amanyathelo okhuseleko kufuneka athatyathwe ukukhusela ubushushu kunye nomphunga owenziwe ngexesha lenkqubo ye-soldering.

isiphelo

Ukuqukumbela, i-soldering ingaba sisisombululo esisebenzayo sokujoyina okanye ukulungisa insimbi engenasici, kodwa idinga ubuchule obuthile kunye nezixhobo. Kukho iindlela ezahlukeneyo ze-soldering zensimbi engenasici, kwaye indlela efanelekileyo ixhomekeke kwisicelo esithile kunye nohlobo lwensimbi engenasici. Xa i-soldering steel stainless, kubalulekile ukusebenzisa i-solder echanekileyo kunye ne-flux ukuqinisekisa ukuba ibhondi eyomeleleyo kunye neyomelele. Ukongezelela, kufuneka kuthathwe amanyathelo okhuseleko afanelekileyo, kwaye ubukhulu bensimbi engenasici bunokuchaphazela inkqubo ye-soldering. Ngelixa i-soldering ingaba sisisombululo esiluncedo, isenokungasoloko iyona nto ilungileyo okanye isisigxina sokulungiswa kwensimbi engenasici. Ezinye izicelo ezixhaphakileyo zokuthengisa ngentsimbi engatyiwa zibandakanya iinkqubo zeHVAC, izixhobo zonyango, kunye nezixhobo ze-aerospace. Ngokubanzi, i-soldering eyimpumelelo yensimbi engenasici idinga ukuqwalaselwa ngokucophelela kwiinkcukacha kunye nobuchule obufanelekileyo bokuqinisekisa ukuba ibhondi eyomeleleyo kwaye ethembekileyo.

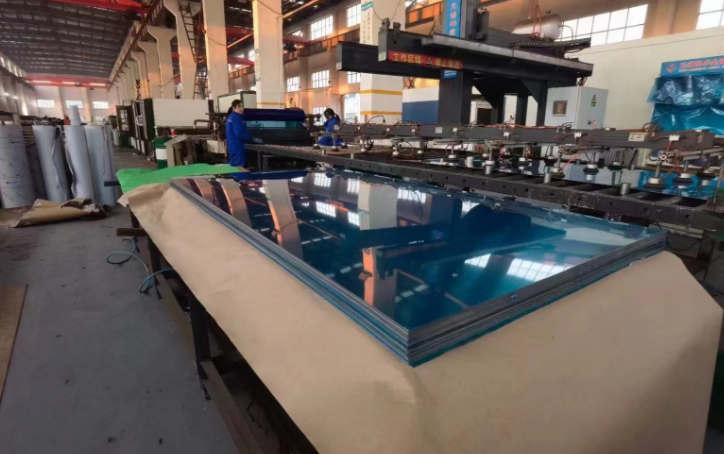

If you want to find a trustworthy stainless steel supplier, we’d advise you to consider Sino Stainless Steel. As a leading supplier of stainless steel products, Sino Stainless Steel provides customers with imicu yentsimbi, iikhoyili zensimbi ezingenasici, iipleyiti zensimbi ezingenasici, amashiti ensimbi engenasici, imivalo steel stainless, yaye iingcingo zentsimbi ngexabiso elikhuphisana kakhulu.

Fumana i-Quote Free

Uluhlu Yemixholo

Izithuba enxulumene

Yintoni umgangatho we-ASTM we-SS bar ejikelezayo?

Iintsimbi ezingqukuva zentsimbi (SS) zithatha indawo ebalulekileyo ngenxa yokusetyenziswa kwazo ngokubanzi kumashishini ahlukeneyo. Umgangatho we-ASTM we-SS bar engqukuva yi

Yintoni ixabiso le-SS bar ejikelezayo?

Ixabiso le-SS bar ejikelezayo sisifundo esintsonkothileyo, esiphenjelelwa zizinto ezahlukeneyo ukusuka kwiindleko zempahla ekrwada, iinkqubo zokuvelisa, imfuno yentengiso, kunye nokubonelela.

Nguwuphi umahluko phakathi komtya kunye neshiti lentsimbi?

Kummandla wobunjineli besinyithi kunye nobunjineli bezinto, umcu kunye neshiti lentsimbi ngamagama amabini ahlala esetyenziswa ngokutshintshanayo, kodwa eneneni, anawo.

Lithini ixabiso le-410 sheet stainless steel?

Kwindawo ye-metallurgy kunye nesayensi yezixhobo, amashiti ensimbi engenasici athatha indawo ebalulekileyo ngenxa yokumelana nokugqwesa kwawo okungaqhelekanga kunye nokuqina. Phakathi kwe

Nguwuphi umahluko phakathi kwekhoyili yeshiti kunye nepleyiti?

Njengengcali enamava kwicandelo lezinto zetsimbi ezivela kwiSino Stainless Steel, ndiye ndadibana neendidi ezininzi zeefom zetsimbi, nganye isebenzela yayo.

: + 86-18621535697

: + 86-18621535697  umthombo:export81@huaxia-intl.com

umthombo:export81@huaxia-intl.com